Discover how Treloar’s 3 Seal Swivel Joints can save you time and money

Having served Australian industries for close to a century, Treloar has evolved into an industry leading supplier of high-quality critical fluid handling products and services. Offering proven and dependable products and high technical standards, we are committed to the continual improvement of our products.

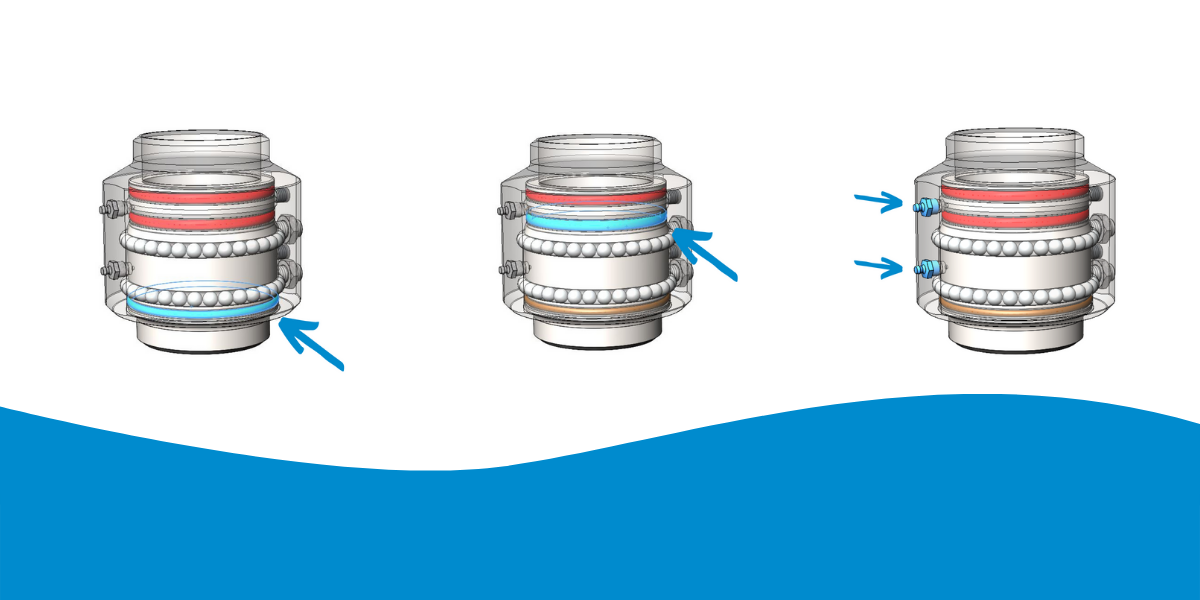

As part of this commitment, significant updates have been made to our range of highly customisable swivel joints including the launch of a 3 Seal Swivel Joint that is sealed from the atmosphere, requires less maintenance and boasts a longer life span.

Significant updates

According to Treloar Engineering Manager, Paul Walton, Treloar’s range of swivel joints have changed significantly over the last 40 years.

“We’re proud of how our swivel joints have evolved over the years with improvements to service intervals and sealing technology. One of the main differences in today’s swivel joints is that we no longer use a felt dust seal so maintenance intervals are significantly improved and the system is now sealed for life,” he said.

“Another major change is that we use o-rings instead of lip seals which allows for more wear in the ball races prior to leaking which extends the swivel joints lifespan.”

“We also have more material options and can accommodate any type of chemical with systems such as Teflon lining or specialist metals,” Paul said.

Range of swivel joints

Treloar offers three types of modern swivel joints that are available in a range of materials, sizes and styles including:

- 3000 Series Fabricated: Body and Tail – this is our lowest cost option which features a new three seal design.

- 5000 Series Fabricated (Split Flange): Flange, Body and Tail – enables you to access and replace seals without removing ball bearings resulting in simple and easily serviceable options.

- HSF series (Hygienic Split Flange): 2 x Flanges, Body and Tail – this swivel joint is highly technical and perfect for food grade applications. Features include a bearing system which can be removed and replaced without welding.

Our range of swivel joints are fully customisable while also offering a wide range of applications. A redundant sealing system ensures the early detection of potential leaks while different greases can be used in the seals and bearings. And because they’re completely sealed to the atmosphere, Treloar’s swivel joints can be used for submerged service.

Treloar’s swivel joints are available in hygienic or food grade standards and include seals that can be replaced without removing the ball bearings on the split flange version. For specialised applications such as acid, caustic or speciality chemicals, we can offer fully imported swivel joints from Europe .

Treloar prides itself on innovative solutions and the application of world-class products to deliver upon our customer’s needs. No matter how challenging the task, we have the skills and technical expertise to develop solutions for your critical fluid transfer challenges. Talk to Treloar to find out how we can help you today.

Learn about the upgrades we've made

.png?width=217&height=65&name=Logo%20(2).png)

Comments