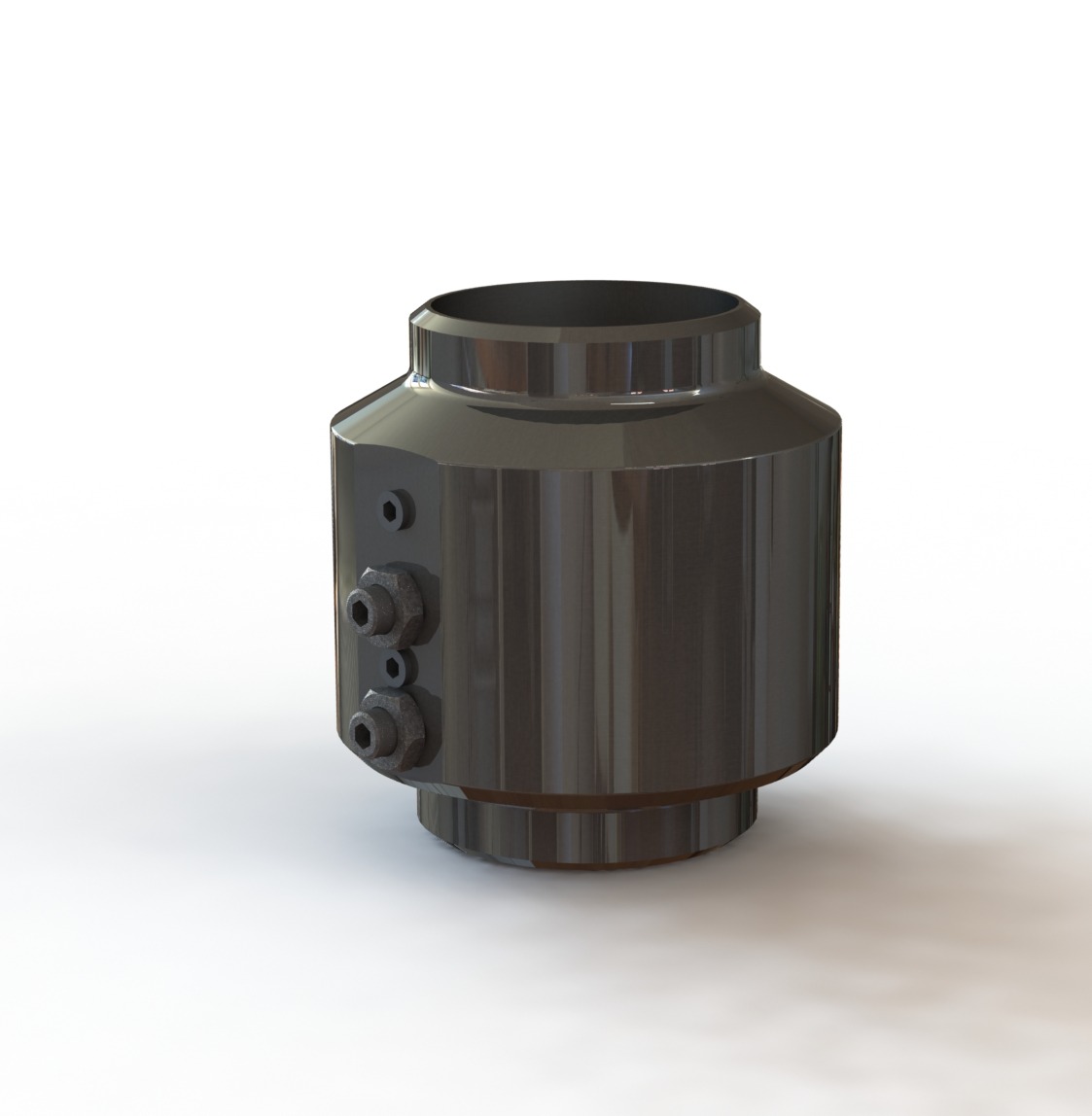

Tired of greasing swivel joints every month and replacing the seals every year?

Tired of the constant struggle with maintaining your swivel joints? We hear you! At Treloar, we understand the frustration of frequent greasing and recurring seal replacements. That's why we've completely revolutionised our swivel joint designs,

Learn about the swivel joint upgrades we've made

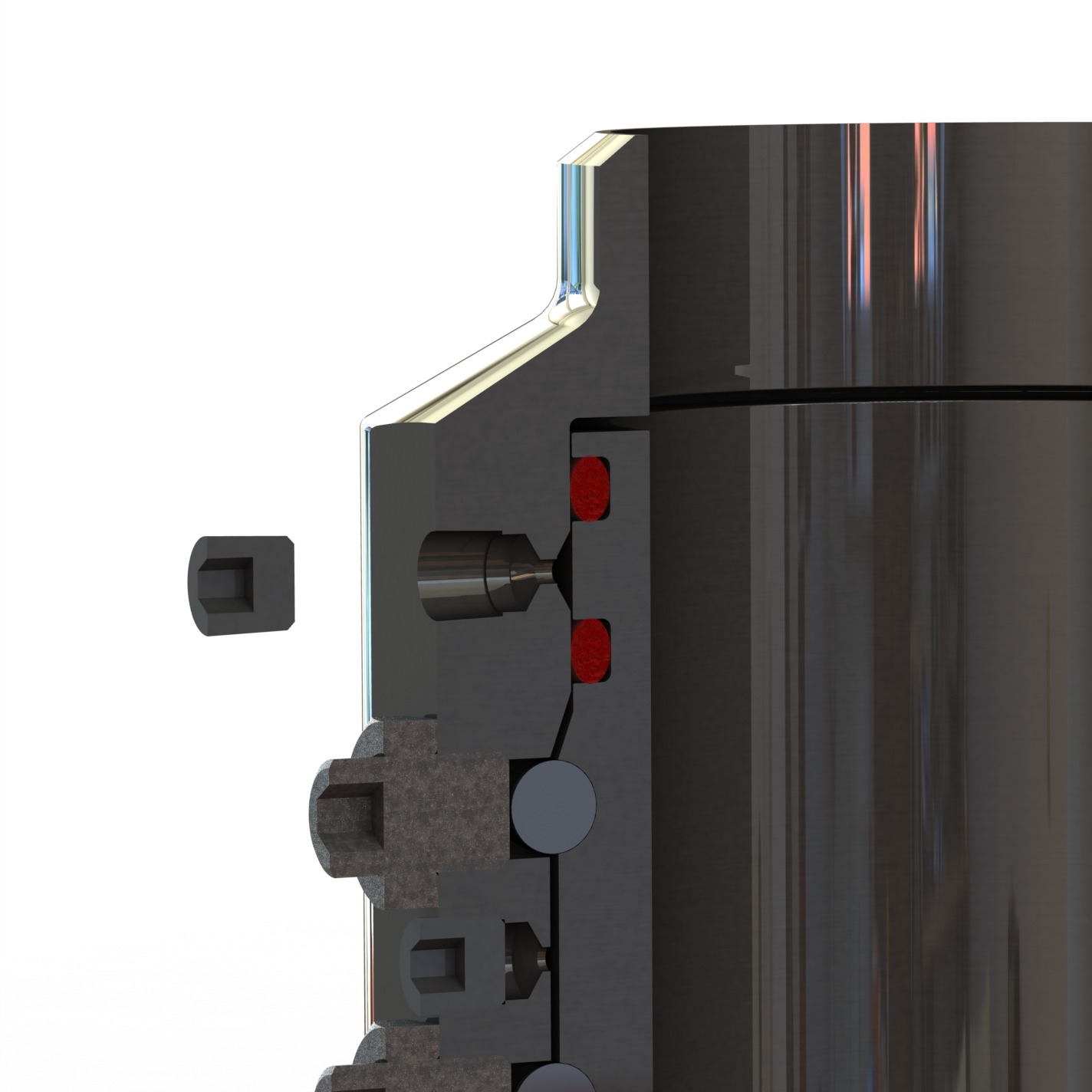

We've engineered a way to check seals are leaking without separating the body and tail so you can easily inspect annually and replace when needed

.png)

We've replaced the dust seal with an o-ring to prevent water ingress, extending life

.png)

We've added a backup seal which allows for planned maintenance

.png)

Seals and bearings can be conveniently greased with different greases in each

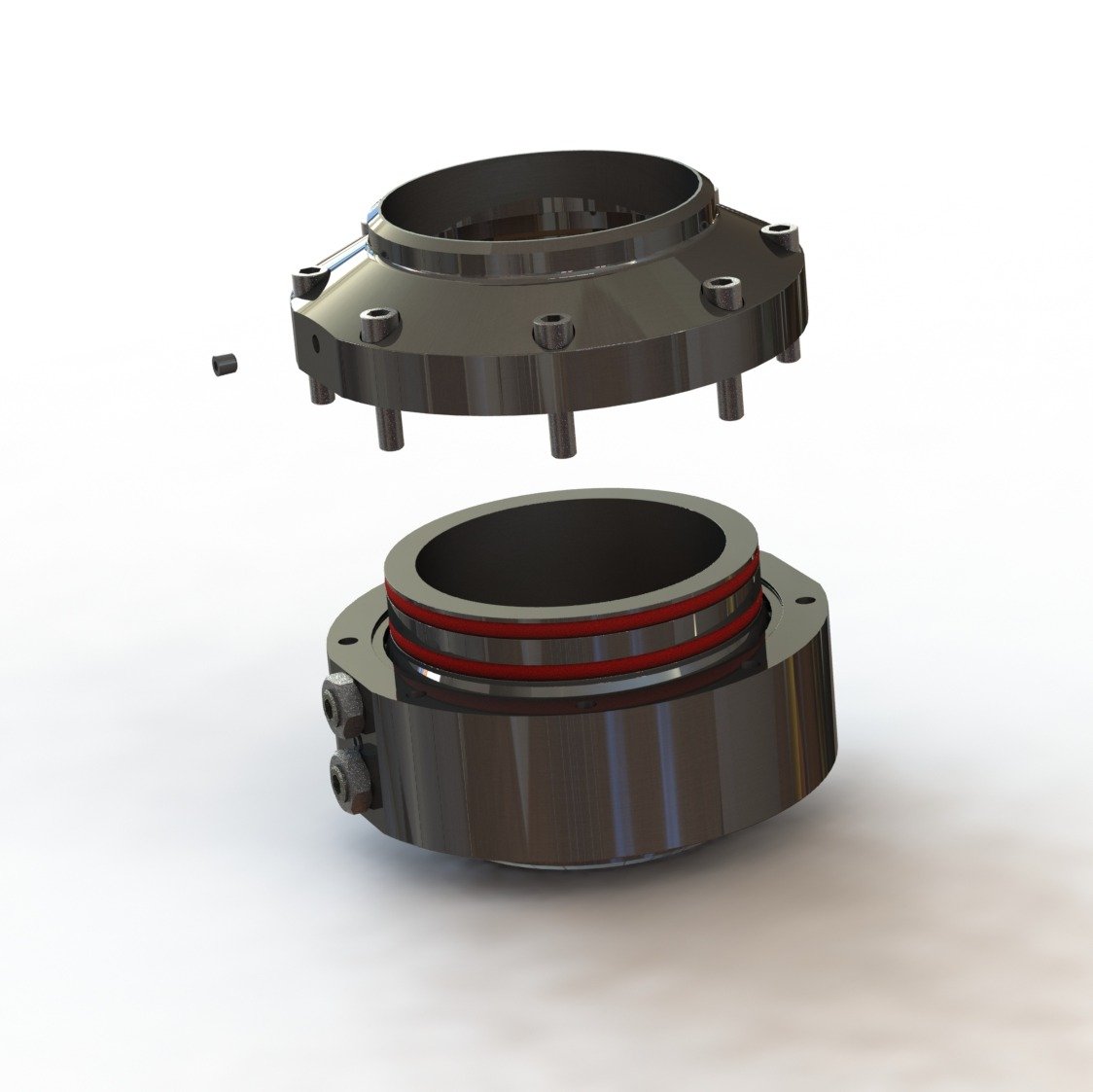

Split flange swivels allow seal replacement without removing ball bearings

.png)

We can provide extreme service swivels from our trusted international partners to handle almost any fluid needing to be transferred (such as acid, caustic or speciality chemicals)

Swivel Joint Maintenance Requirement Improvements

Say Goodbye to Monthly Greasing:

One of the most significant improvements is the extended greasing interval. Our new swivel joints only require lubrication annually, a drastic reduction compared to the monthly greasing routines of traditional models. This translates to significant time savings and reduced maintenance costs for your operation.

Effortless Seal Inspection and Replacement:

Another pain point addressed is seal maintenance. Previously, inspecting for worn seals often meant a time-consuming disassembly process. Our upgraded swivel joints feature a cleverly engineered leak detection port. This allows for a simple annual inspection to determine seal integrity, eliminating unnecessary disassembly and maximizing uptime.

Enhanced Durability for Extended Service Life:

We've gone beyond just reducing maintenance frequency. Our new swivel joints boast superior durability thanks to a series of strategic upgrades. We've replaced the traditional dust seal with a more robust o-ring, effectively preventing water ingress, a major contributor to premature seal wear. Furthermore, we've incorporated a backup seal, providing an extra layer of protection and extending the overall lifespan of your swivel joint.

Unparalleled Convenience and Flexibility:

For even greater convenience, our new swivel joint design allows independent greasing of seals and bearings with different greases, catering to specific application requirements. Additionally, the split flange design facilitates easy seal replacement without removing the ball bearings, further streamlining maintenance procedures.

Extreme Service Solutions:

Our commitment to innovation extends beyond standard applications. We understand that some operations require swivel joints capable of handling highly specialized fluids. To address this need, we offer a selection of extreme service swivel joints sourced from our trusted international partners. These robust joints are designed to withstand harsh environments and handle a wide range of fluids, including acids, caustics, and specialty chemicals, ensuring reliable performance in even the most demanding situations.

Old Swivels |

New Swivels |

|

| Grease Swivel Joint | 1 month | 1 year |

| Replace Dust Seal / O-Ring | 1 year | Replace O-ring(s) when required – Leak detection port allows annual inspection to determine if seal need to be replaced before a leak occurs |

3000-1

3000-2

5000-1

5000-2

HSF-1

HSF-2

Treloar Swivel Joints

3000 Series swivel joints are available in a variety of materials, sizes and styles to meet virtually any application.

- Standard Sizes: 3/4 in. to 12 in.

- Standard Materials: Aluminum, Bronze, Carbon Steel, Ductile Iron, Stainless Steel

- Standard Seals: Buna-N, Fluorocarbon, PTFE, EPDM, Neoprene

- End Connections: FNPT, 150/300 ANSI Flanges, Butt/Socket Weld

Treloar has three types of swivel joints available from manufactured & cast, to highly engineered:

- 3000 series fabricated; Body and Tail – new 3 seal design. Lowest cost options

- 5000 series fabricated (Split flange); Flange, Body and tail – access and replace seals without removing ball bearings. Simple and easily serviceable options

- HSF series (Hygienic split flange); 2 x Flanges, Body and Tail – bearing system can be removed and replaced with no welding. Highly technical, can be used in food grade applications.

Treloar Swivel Joints are made in Australia.

Our commitment to quality extends to every step of the process, from machining and heat-treating to assembly and testing – all conducted right here in the Hunter Valley.

.png?width=400&height=401&name=Untitled%20design%20(51).png)

Don't settle for the constant hassle of traditional swivel joint maintenance. Experience the peace of mind and efficiency that come with our revolutionary new swivel joints. Contact Treloar today to discuss upgrading your operation and eliminating swivel joint headaches for good.

Please complete the form below and we will get in touch with you.

.png?width=217&height=65&name=Logo%20(2).png)