Project Overview: Visy Floating Suction Project

PROJECT BRIEF

Visy is a global leader in the packaging, paper and resource recovery industries. They have been providing high quality, innovative and sustainable packaging products and solutions in Australia for over 70 years. Visy recently approached Treloar with a challenging problem - they needed an innovative solution for the removal of unwanted oil from the surface of a foul condensate that is used in their paper production process.

With a corrosive and flammable chemical involved, and several other hurdles to overcome, the brief certainly presented a challenge, but it was exactly the sort of challenge that Treloar specialises in.

The Treloar team commenced a process of scoping the project and developed a solution that incorporated their floating suction units.

CHALLENGES

This retro-fit project required the Treloar team to navigate a range of requirements and specifications including a need for precise calculations and measurements.

The most pressing challenge was the timeline. The condensate is full year round with the exception of just one week in October when it is empty. Therefore, the timeline needed to incorporate design, manufacture and completion in time for dispatch in October.

As outlined in the brief, Treloar was dealing with a condensate that contained a corrosive and flammable chemical, so their solution needed to incorporate materials that could withstand this. A very low submergence was required in order to remove only the very top layer of oil on the surface.

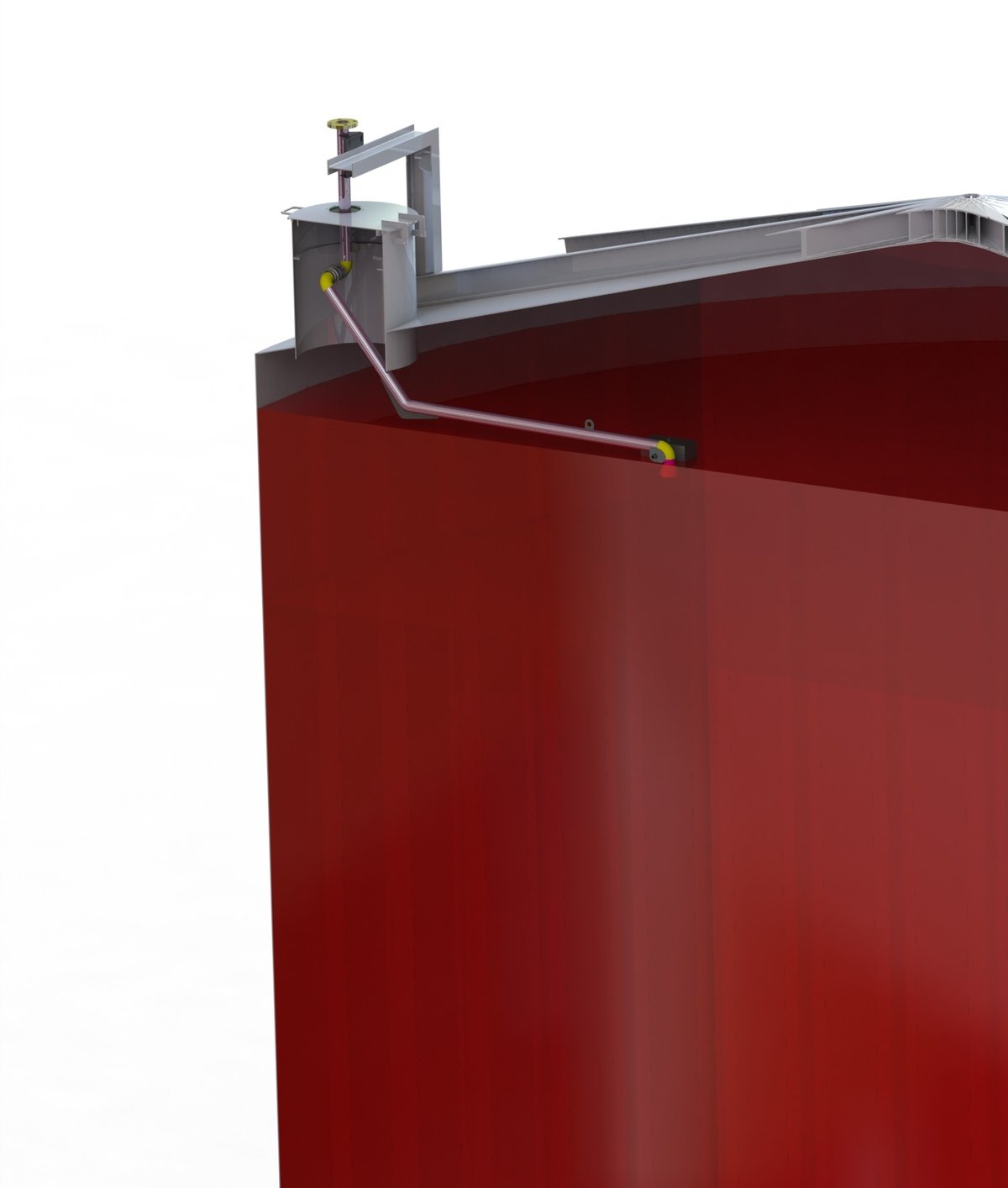

To further complicate things, the space available for installation was very limited and there was no particular place for mounting the floating suction, so Treloar needed to incorporate an external support in a design that allowed the manway to remain operable. The installation would then need to take place with the solution installed in one piece, through the manway.

SOLUTION

The Treloar team designed a solution that utilises a stainless steel construction in order to handle the corrosive and flammable nature of the chemical.

To address the low submergence requirement,, Treloar custom designed floats with a very low and adjustable submergence allowance.

To navigate the installation challenges, Treloar developed a solution that could be installed through the existing manway and included a no flanged nozzle and bent tubing to allow installation without entering the tank and internal manway sealing to prevent water ingress.

PROGRESS

In the coming weeks, Treloar will publish progress updates through to completion. Stay tuned to hear from us on this innovative solution for Visy.

.png?width=217&height=65&name=Logo%20(2).png)

.png)

Comments